In the ever-evolving landscape of 3D printing technology, innovations continually push the boundaries of what’s possible. One such groundbreaking development is the Mosaic Palette, a device that enables multi-material 3D printing. This article aims to delve deep into the workings of the Mosaic Palette, exploring its functionality, benefits, applications, and the impact it has on the world of additive manufacturing.

Understanding Multi-material 3D Printing

Traditional 3D printers work with a single material, typically plastic filament. While this is suitable for many applications, it limits the complexity and functionality of printed objects. Multi-material 3D printing addresses this limitation by allowing the use of multiple materials in a single print job.

The concept of multi-material 3D printing opens up a world of possibilities. Objects can be printed with varying degrees of flexibility, transparency, color, and even conductivity. This versatility has significant implications across industries, from healthcare and aerospace to fashion and consumer goods.

Introducing the Mosaic Palette

At the forefront of multi-material 3D printing is the Mosaic Palette. Developed by Mosaic Manufacturing, the Palette is a compact device that integrates seamlessly with existing 3D printers, transforming them into multi-material powerhouses.

The core functionality of the Mosaic Palette lies in its ability to combine multiple filaments into a single strand, which is then fed into the 3D printer. This process, known as filament splicing, enables the creation of intricate, multi-colored, and multi-material prints without the need for complex machinery.

How Does the Mosaic Palette Work?

The Mosaic Palette operates through a series of precise mechanisms that ensure seamless filament splicing and coordination with the 3D printer.

- Filament Inputs: The Palette can accept up to four different filaments simultaneously. These filaments can be of varying materials, colors, and diameters, providing extensive flexibility in material selection.

- Splicing Mechanism: As the filaments enter the Palette, they are guided to a splicing unit. Here, the filaments are cut, aligned, and fused together using heat. This fusion creates a single, multi-colored/multi-material filament.

- Buffering and Coordination: The spliced filament is then fed into a buffer, which ensures a consistent and uninterrupted flow to the 3D printer. The Palette coordinates with the printer to synchronize filament changes and color/material transitions seamlessly.

- Software Integration: Mosaic provides intuitive software that accompanies the Palette. This software allows users to create and customize multi-material prints with ease. It handles filament management, color/material mapping, and transition points, simplifying the printing process.

Benefits of Using the Mosaic Palette

The Mosaic Palette offers a host of advantages that make it a game-changer in the realm of 3D printing:

- Enhanced Versatility: With multi-material capabilities, users can create prints with varying properties such as rigidity, flexibility, transparency, and color gradients.

- Cost Efficiency: Instead of investing in specialized multi-material printers, users can upgrade their existing single-material printers with the Palette. This cost-effective approach democratizes multi-material printing and makes it accessible to a broader audience.

- Reduced Waste: By utilizing filaments efficiently and minimizing material transitions, the Palette helps reduce waste during printing. This is particularly beneficial for environmentally conscious users and businesses.

- Complex Designs Made Simple: The Palette simplifies the process of creating complex, multi-colored prints. Users can focus on design creativity without worrying about the technical complexities of multi-material printing.

- Improved Print Quality: Filament splicing is done with precision, resulting in high-quality prints with seamless color transitions and material changes. This level of detail enhances the aesthetic appeal of printed objects.

Applications of Multi-material 3D Printing with the Mosaic Palette

The versatility of the Mosaic Palette lends itself to a myriad of applications across various industries:

- Prototyping and Product Development: Engineers and designers can create functional prototypes with varying material properties, simulating the characteristics of final products accurately.

- Customized Consumer Goods: From personalized phone cases to unique home decor items, the Palette enables the customization of consumer goods with intricate designs and multiple colors/materials.

- Medical and Healthcare: Multi-material printing is revolutionizing healthcare with applications such as prosthetics, medical models, and custom implants that require specific material properties.

- Educational Tools: Educational institutions leverage multi-material printing for interactive learning tools, anatomical models, and scientific demonstrations that benefit from realistic textures and colors

- Art and Fashion: Artists and fashion designers use the Palette to create intricate artworks, jewelry, and fashion accessories that blend different materials and colors seamlessly.

Impact on the 3D Printing Industry

The introduction of the Mosaic Palette has had a significant impact on the 3D printing industry:

- Advancing Innovation: Multi-material capabilities drive innovation by enabling the creation of more complex and functional objects. This paves the way for new applications and advancements in various sectors.

- Market Expansion: The accessibility of multi-material printing through devices like the Palette expands the market by attracting new users, including small businesses, hobbyists, and educational institutions.

- Eco-friendly Practices: Efficient filament usage and reduced waste align with sustainability goals, making multi-material printing with the Palette environmentally friendly compared to traditional manufacturing methods.

- Competitive Edge: Businesses that adopt multi-material printing gain a competitive edge by offering unique, customized products that stand out in the market.

- Collaborative Ecosystem: The Mosaic community fosters collaboration and knowledge-sharing among users, driving collective innovation and problem-solving in the 3D printing community.

Future Developments and Challenges

Looking ahead, the future of multi-material 3D printing with devices like the Mosaic Palette holds exciting possibilities:

- Advanced Material Compatibility: Continued research and development may expand the range of materials compatible with the Palette, including conductive filaments, biocompatible materials, and composites.

- Integration with Industry 4.0: Integration with Industry 4.0 technologies such as AI, IoT, and automation could streamline the multi-material printing process further, enhancing efficiency and scalability.

- Regulatory Considerations: As multi-material printing evolves, regulatory frameworks may need to adapt to ensure safety, quality standards, and material compliance in various applications, especially in sectors like healthcare.

- Education and Skill Development: Training programs and educational resources will play a crucial role in empowering users to leverage multi-material printing effectively, fostering innovation and skill development.

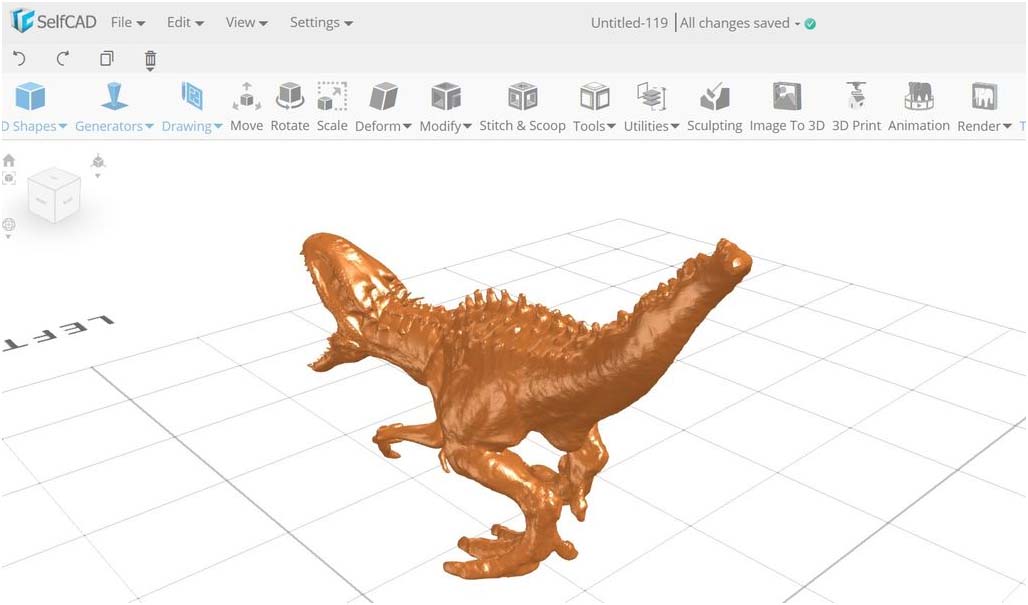

SelfCAD: The Best 3D Printing Software

SelfCAD stands out as one of the premier choices among 3D printing software solutions, offering a comprehensive suite of tools designed to empower creators at all skill levels. Here’s a closer look at why SelfCAD is regarded as the best 3D modeling and 3D printing software by many enthusiasts and professionals alike:

- User-Friendly Interface

One of SelfCAD’s standout features is its intuitive and user-friendly interface. Whether you’re a beginner or an experienced designer, the software’s layout and tools are designed to be easily navigable and accessible. This accessibility makes it a top choice for those just getting started in the world of 3D printing.

- All-in-One Platform

SelfCAD takes the concept of convenience to the next level by offering an all-in-one platform. Users can access a wide range of tools and functionalities within a single software environment, eliminating the need to switch between multiple programs for modeling, sculpting, and slicing.

- Powerful Modeling Tools

From parametric modeling to advanced mesh editing, SelfCAD provides a robust set of modeling tools that allow users to bring their ideas to life with precision and creativity. Whether you’re designing prototypes, artistic sculptures, or functional objects, SelfCAD’s modeling capabilities offer versatility and control.

- Integrated Sculpting Features

For artists and sculptors, SelfCAD offers advanced sculpting features that enable intricate detailing and organic shaping. The software’s sculpting tools are designed to mimic traditional sculpting techniques, making it easy to sculpt digital clay and create complex designs with ease.

- Seamless Slicing and Printing

SelfCAD’s integrated slicing feature streamlines the preparation process for 3D printing. Users can optimize their prints, generate support structures, and preview the printing process within the software, ensuring a seamless transition from design to physical object.

- Extensive Library and Resources

In addition to its robust toolset, SelfCAD provides access to an extensive library of pre-designed models, shapes, and templates. This library serves as a valuable resource for inspiration and quick prototyping, allowing users to jumpstart their projects and explore new design ideas.

- Affordable Pricing

Despite its comprehensive features and capabilities, SelfCAD maintains an affordable pricing model. This accessibility makes it an attractive option for hobbyists, educators, and small businesses looking to leverage advanced 3D printing software without breaking the bank.

In summary, SelfCAD stands out as the best 3D printing software thanks to its user-friendly interface, all-in-one platform, powerful tools, seamless integration, extensive resources, and affordable pricing. Whether you’re a beginner exploring the world of 3D design or a seasoned professional pushing the boundaries of innovation, SelfCAD offers the tools and support you need to bring your creative visions to life.

Conclusion:

In conclusion, the Mosaic Palette represents a paradigm shift in the world of 3D printing, unlocking new possibilities for creativity, customization, and functionality. Its seamless integration with existing printers, coupled with intuitive software and precise filament splicing, makes multi-material printing accessible to a diverse range of users. As technology continues to evolve and user adoption grows, the impact of devices like the Mosaic Palette will continue to shape the future of additive manufacturing and innovation across industries.